ARMI is a project aimed at designing a sustainable agricultural research and production site in South Korea. With only 22% of the country’s land being arable due to its mountainous terrain, the initiative focuses on transforming a site in the Gyeongsangbuk-do area into a hub for innovative agricultural practices.

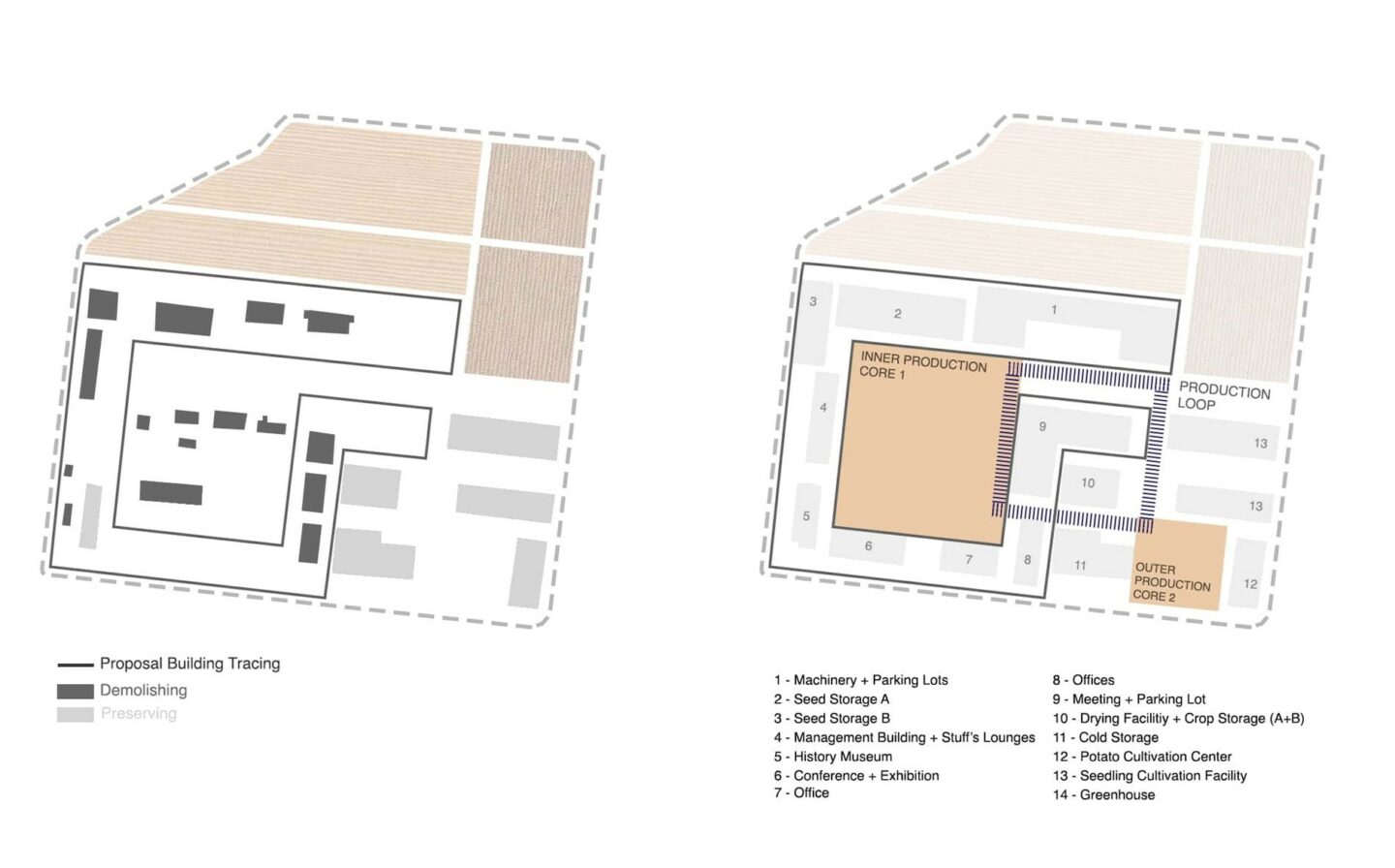

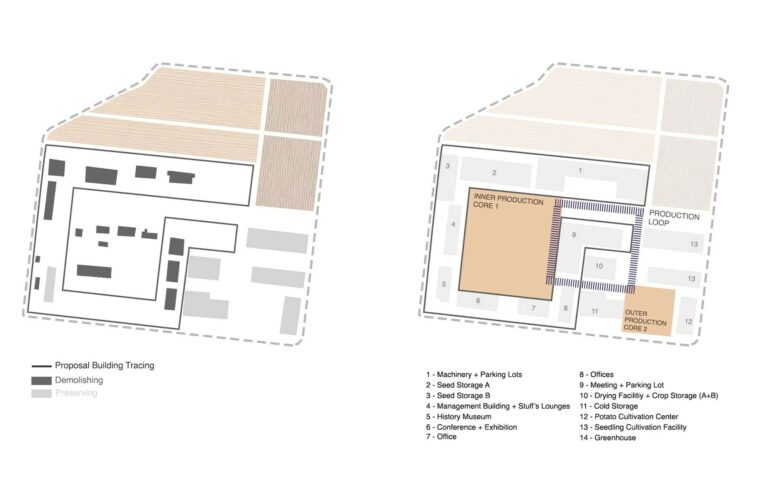

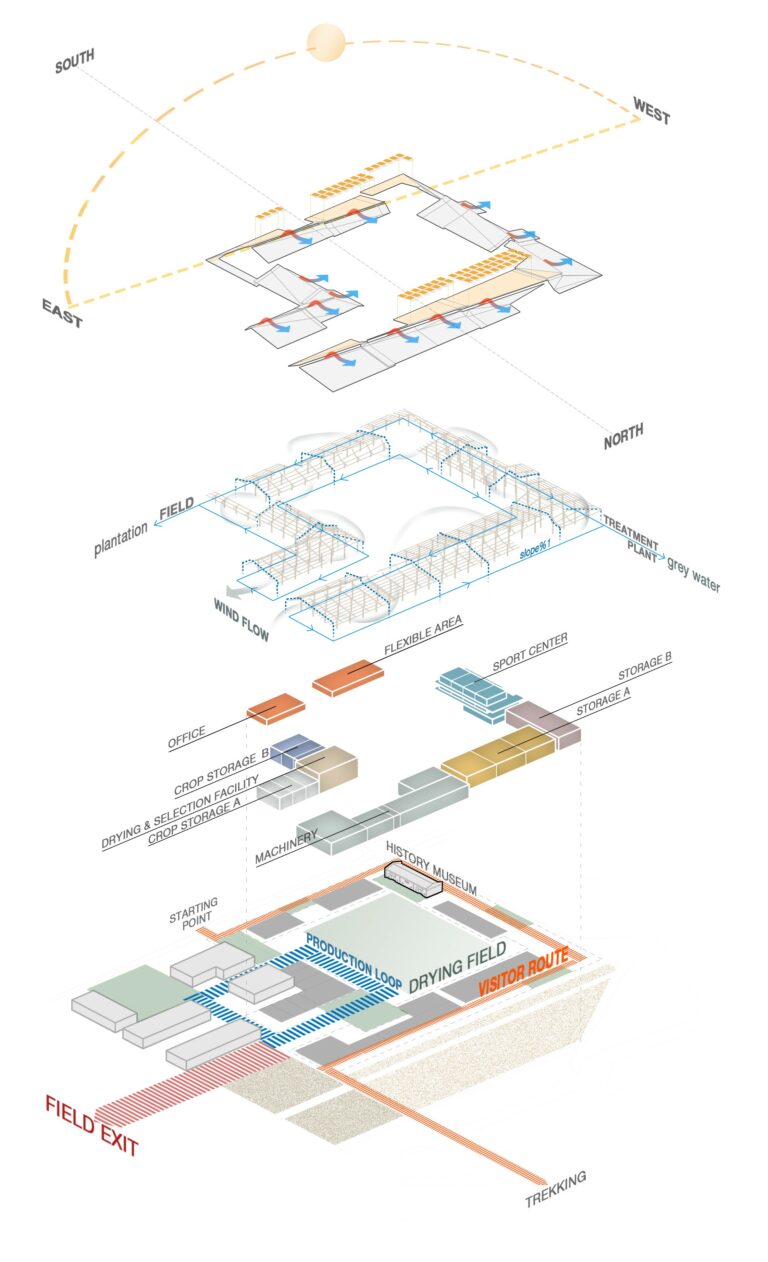

The design strategy encompasses tracing and minimizing the footprint of demolished structures, preserving farmlands by leaving the majority of the site untouched, and compacting buildings to establish efficient production cores. By integrating renewable energy sources, optimizing water usage, and managing the production cycle, ARMI seeks to create a harmonious balance between agriculture, technology, and environmental conservation.

Production Cycle & Efficiency (From Core to Cycle)

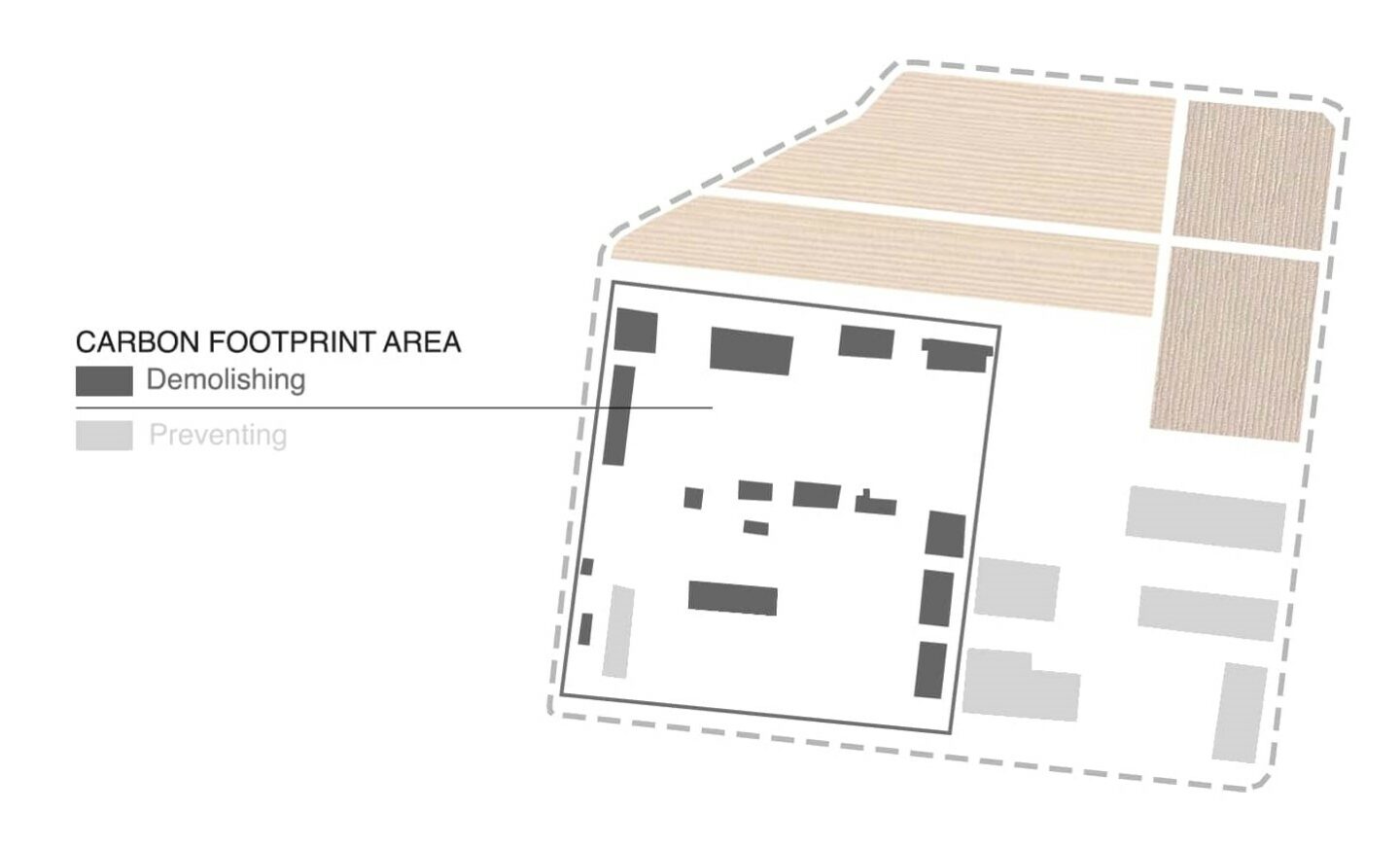

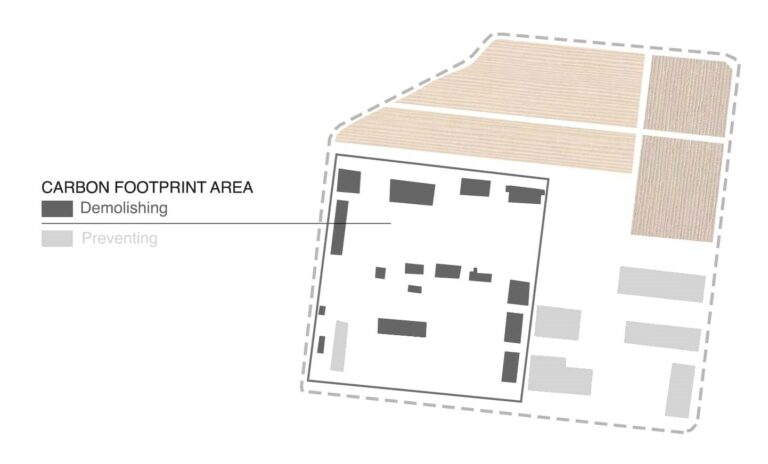

The next focus of this project is to try to reduce carbon emissions by bringing together vehicles and programs with high carbon footprints. It creates an internal profuction core by following the existing carbon footprint to be articulated to the protected buildings. These two efficient cores are connected with the production cycle and their output to the field is provided.

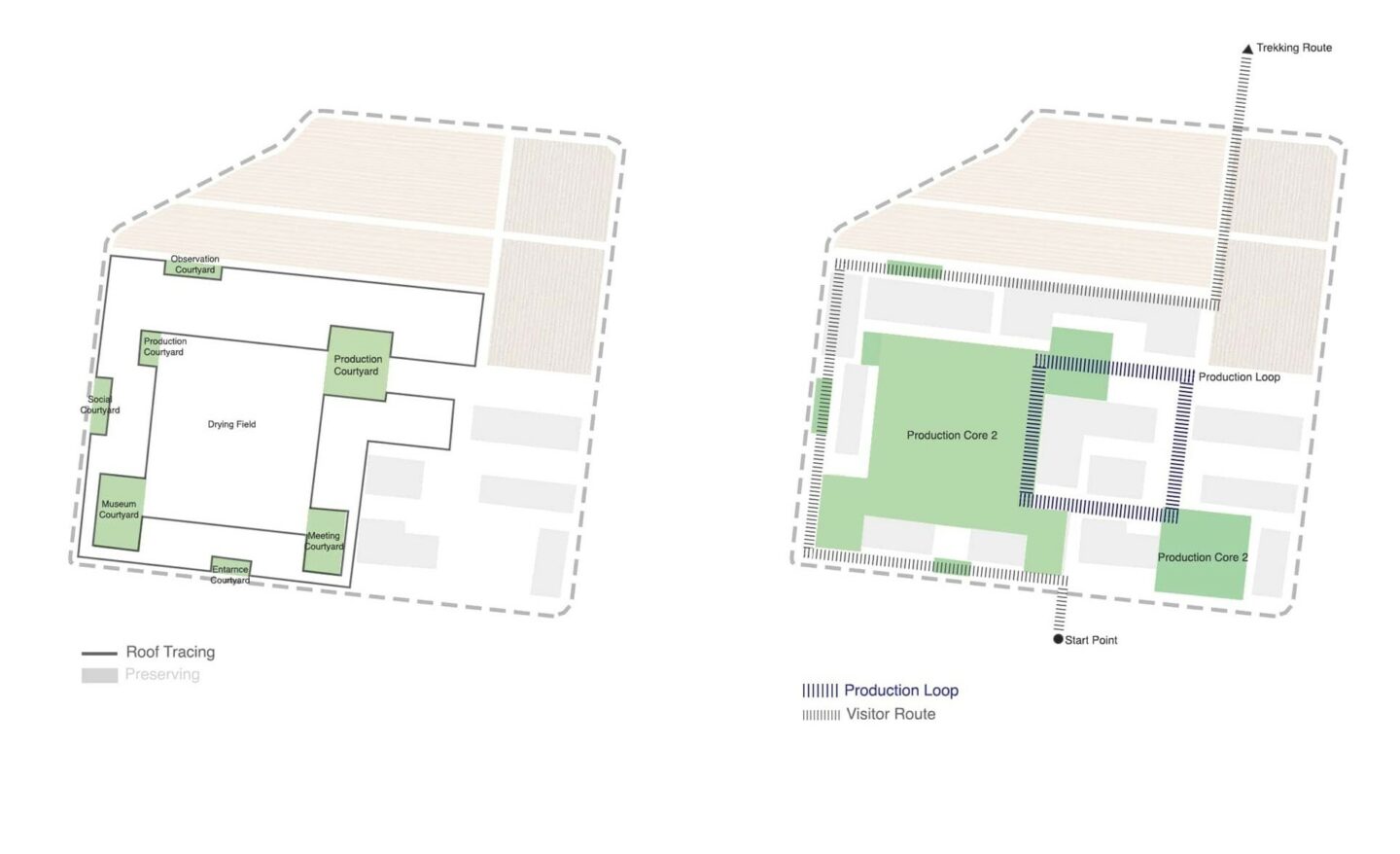

Conserving the natural areas around the carbon footprint islands and transforming them into production areas is one of the other focuses of the project. Social production areas are built around the production core for service vehicles and workers, aiming to increase productivity and motivation to work together.

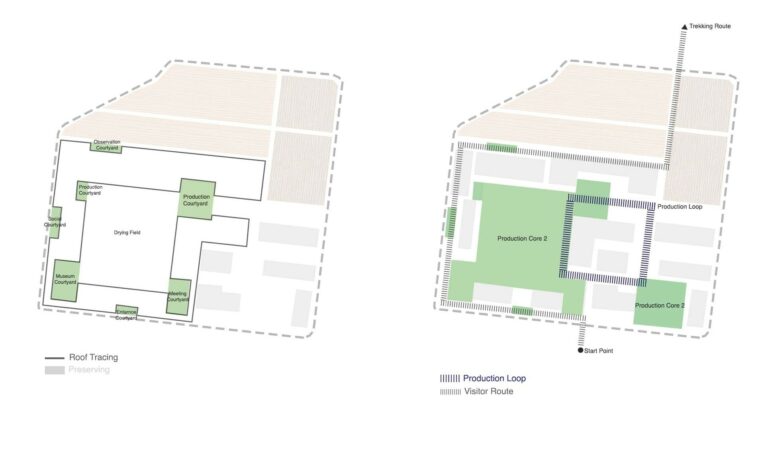

The visitor is considered both as a part of the site and as an observer. An experience route is being constructed at the intersection of production and agriculture. On this line, the visitor sometimes connects with the production core and sometimes leaves the island for trekking by integrating with the agricultural landscape.

SUSTAINABILITY STRATEGIES

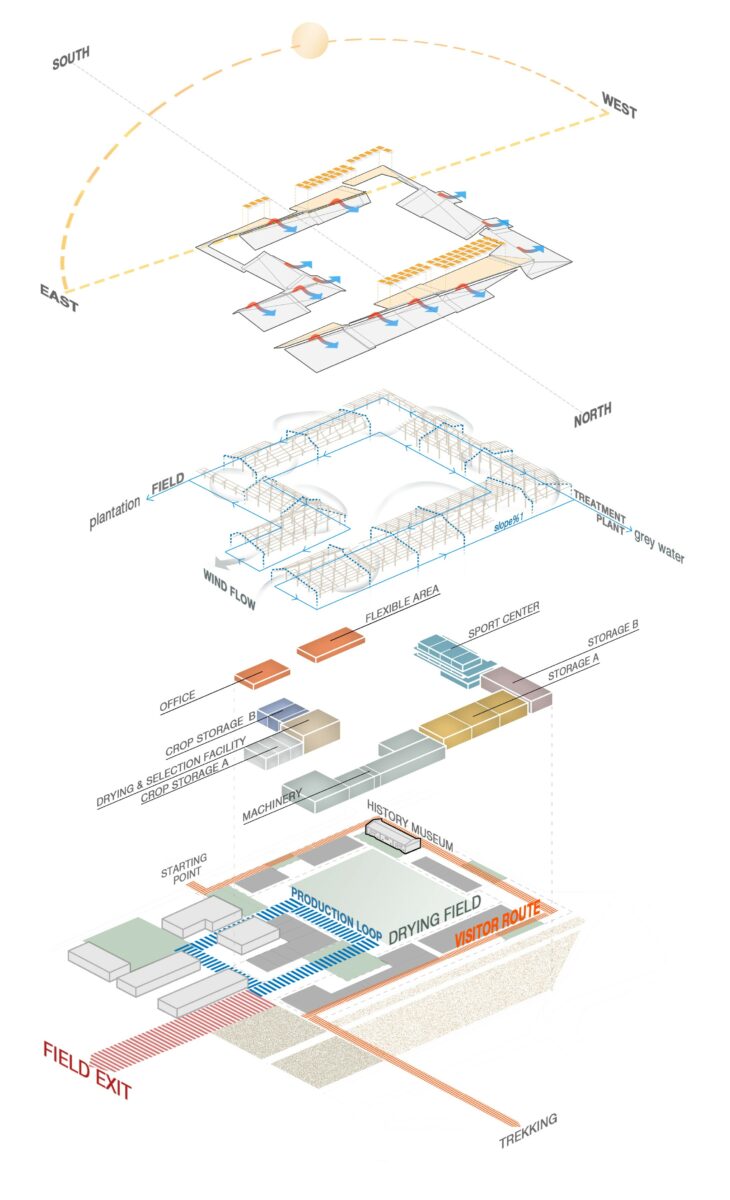

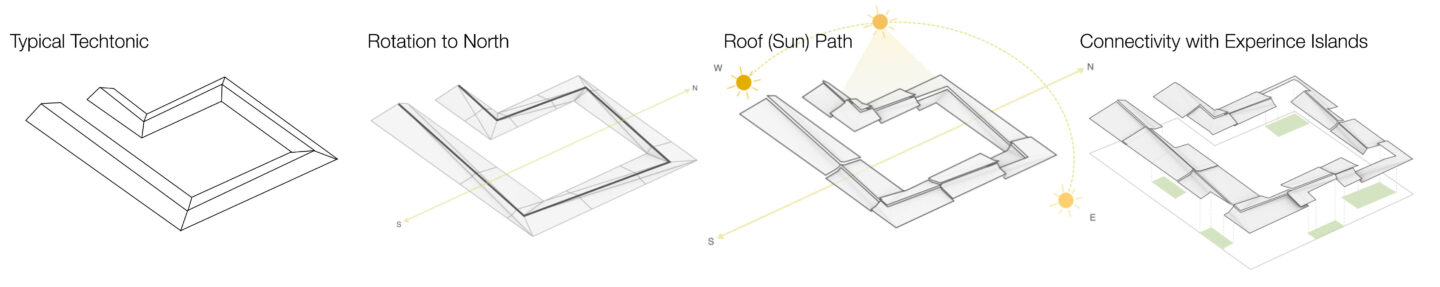

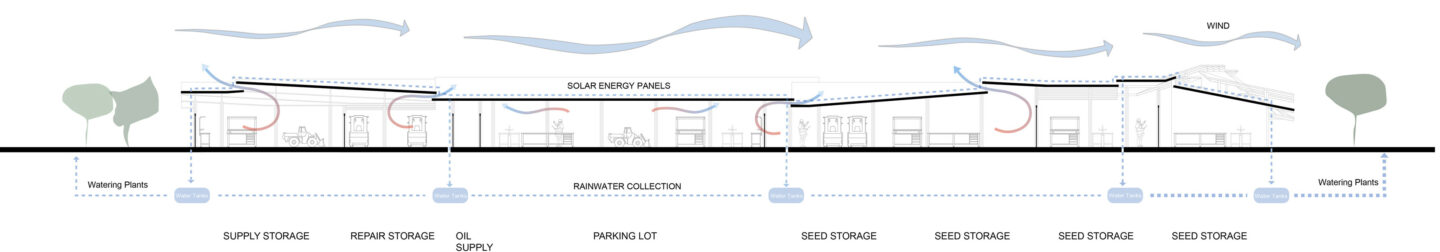

Sun & Wind

The roof shapes its relationship with light and wind with the print on it. The roof track, located on the East-West axis, receives the sun from the north and with reverse light, both illuminating the spaces and trying to prevent the effects of overheating and glare.

Solar panels are placed on the south-facing sides of the roofs, focusing on renewable energy to get the most efficiency with minimum equipment.

Roofprint uses the wind as a wind trap by taking it to the drying area at a parallel angle. Thus, the crops in the field dry faster and passively contribute to increasing production efficiency. It is aimed to create maximum cross ventilation by placing the roof openings in warehouse and production areas in such a way that they do not interfere with each other.

Machine functions such as supply storage, repair storage, and parking lot are located at the entrance where air circulation is high. By increasing the roof heights in these areas, it is aimed that the air heated by the engine temperature rises and leaves the space quickly.

Water Efficiency

Roof slopes are formed to transfer rainwater slowly, to prevent losses that may occur, and to store rainwater in a controlled manner. While some of the collected rainwater returns to the structure as gray water, some of it passes through the filter and is given to the field as fertilizer irrigation as a curative for plants.

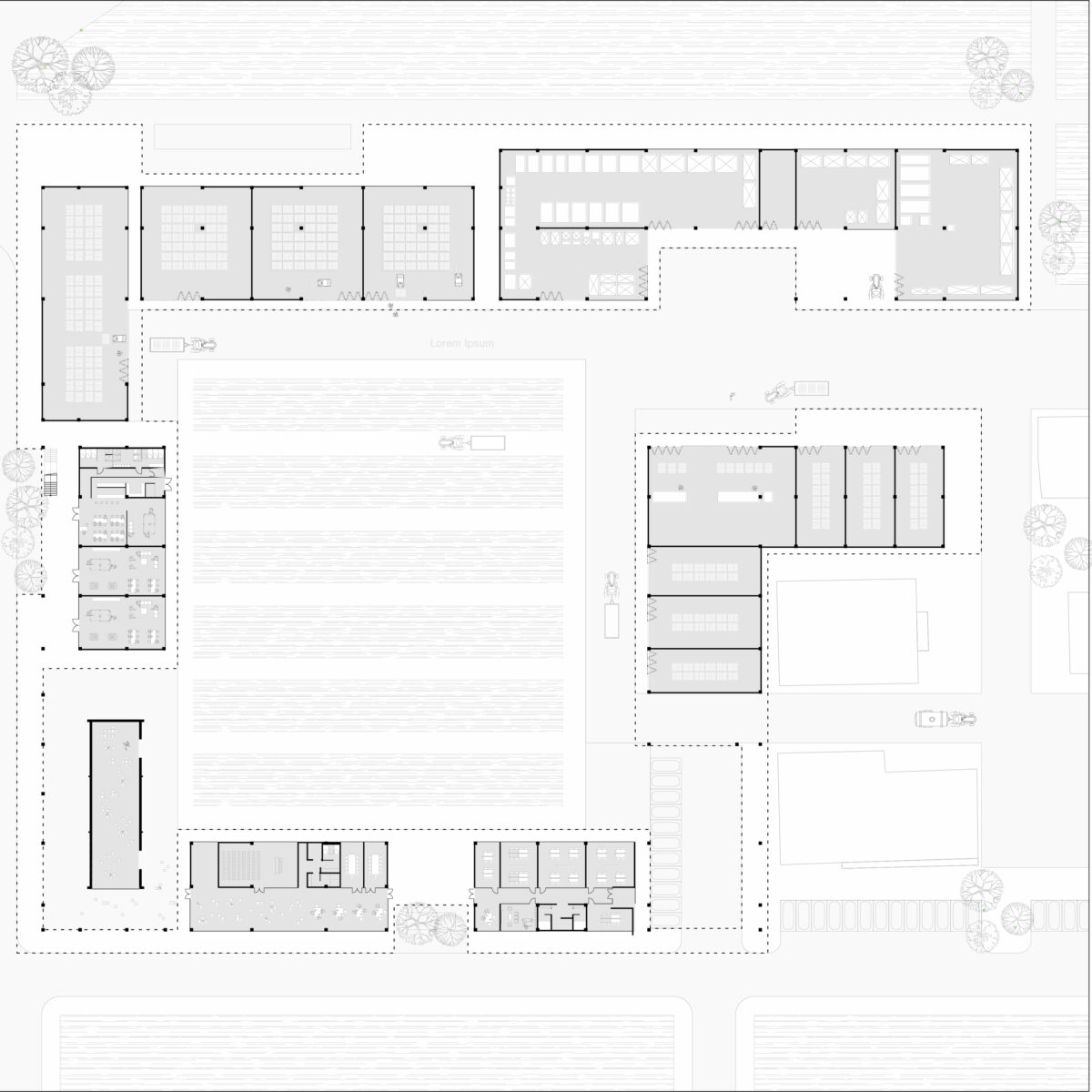

1- Supply Storage

2- Repair Storage

3- Oil Supply

4- Parking Lot 1

5- Parking Lot 2

6- Seed Storage A

7- Seed Storage B

8- Sport Center

9- Lounge

10- History Museum

11- Conference room

12- Exhibition

13- Meeting Room

14- Office

15- Parking 1

16- Crop Storage A

17- Drying Facility

18- Crop Storage B

19- Cold Storage

20- Cultivation Center

21- Parking 2

Production Cycle Management

Program islands settle by following the carbon footprint of demolished buildings and attempting to hold onto existing ground. Experience islands focus on preserving fertile land in the area. The production cycle is positioned to enable the vehicles to do the most work with the least efficiency and opens directly to the field. Structural construction is created by bringing prefabricated wood to the site and joining them together. Materials are selected from local and nearby production sites, aiming to reduce the carbon management cycle.